High-Speed Labeling Systems

Accurately keep up with the demand from busy distribution centers and production lines.

Fast, Accurate Labeling

Weber Can Help You Meet Your Labeling Requirements

Distribution centers need to label variable sized cartons at ever increasing line speeds with accurate shipping information. And they need that labeling system to be reliable and cost-effective.

Do your demands include product traceability, quality assurance, tracking and tracing in logistics or individual identification of products for just-in-time production? Weber has the answer.

- The Alpha HSM label applicators are modular high-speed labelers that can operate in tandem for zero-downtime labeling.

- The Model LA-6000 is a variable-height label printer-applicator that can print and apply labels to a wide range of package sizes on the same line.

- And the new Legi-Flex 6100 is a high-speed label printer applicator system that prints a label and applies it to match the orientation of the package on the conveyor line.

Pharma

High-speed track & trace labeling for healthcare and pharmaceutical products.

Distribution

Print and apply labels to packages of variable heights and at different angles.

Food

Apply labels to food products with zero-downtime reliability even on recessed areas.

The Future of Labeling

Alpha HSM Label Applicators

Every packaging line is different, so Weber engineered the modular Alpha HSM so that it can be ordered in ten different versions to fit just about any labeling application.

Available in right- or left-hand versions, the Alpha HSM has 5.3” (135mm), 7.8” (200mm), 9.8” (250mm) and 12.6” (320mm) label width versions. The HSM can keep up with line speeds up to 500 feet/minute.

With a labeling accuracy of ±0.01”, the Alpha HSM can handle labels as small as 0.39” x 0.39” (10mm x 10mm) and up to 12.5” x 78.7” (320mm x 2000mm) (W x L).

Depending on the label width configuration, the HSM can use standard 12" OD label rolls or optional 19” OD rolls on 3” diameter cores.

All the systems feature multiple interfaces allowing connections for HMI display, product detector, rotary encoder, I/O signal, Ethernet network, and an aux in and aux out for sensor attachment.

Model LA-6000

Distribution centers need to label variable sized cartons at ever increasing line speeds with accurate shipping information. And they need that labeling system to be reliable and cost-effective.

Do your demands include product traceability, quality assurance, tracking and tracing in logistics or individual identification of products for just-in-time production? Weber has the answer.

Weber’s new LA-6000 high-speed variable-height print-apply system will label passing cartons of varying heights quickly, accurately and efficiently.

The servo motor driven actuator will ensure label application at up to 2250 cycles per hour depending on label size. Carbon fiber components reduce the weight of moving parts for higher labeling speeds.

And with the LA-6000's modular design and large 13.8" O.D. label rolls, you can print and apply labels with a minimum of downtime.

Using the tamp-blow method, the LA-6000 can print and apply up to 40 labels per minute (dispensing output depends on label size, text change and dispensing stroke) to products that vary in height up to 19.68” (500mm). And label placement accuracy is ±0.03” (1mm).

• Interchangeable dispensing heads allow the use of different label sizes.

• Print engines by leading manufacturers such as Zebra and SATO allows an optimal match to the application and its specific printing requirements. (Thermal-transfer or direct-thermal.)

Legi-Flex 6100 SLAM

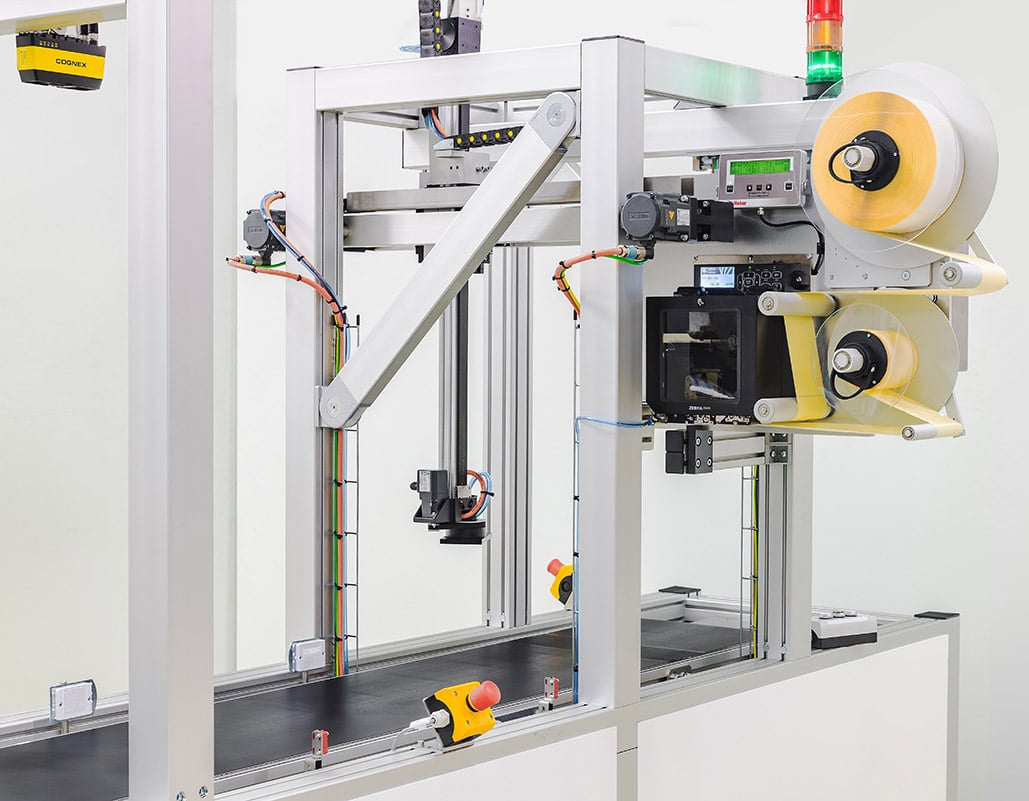

Coming soon from Weber is the new Legi-Flex 6100 SLAM high-speed, variable height and angle print-apply system. This label printer applicator is made for the high-volume world of distribution centers and warehouses and is available in single (shown) or dual applicator versions (zero-downtime version).

Using optical recognition and high-speed servo drive motors, this system can print and apply a label perpendicular to a product on a production line at any angle or product height. The tamp pad rotates to match the angle of the product so the label is on straight.

The applicators are serviceable from the outside of the system and labels can be resupplied quickly. Contact us for more details.