Paper or plastic?

You have heard this question in the grocery store. However, what do you do when you need a labeling solution to this adage old question? When it comes to labeling, many factors come into play that you may not have even considered. Paper versus plastic refers to both the substrate (what the label is being applied to) and the actual label material itself (paper versus film face sheet).

In labeling, substrate refers to the surface onto which a label is applied. In printing, substrate refers to the surface that is to be printed, meaning that the face material (and top coatings) of a label may also be referred to as a substrate.

The substrate the label is applied is a great starting point to determine the type of adhesive and material that will perform best in the application. The most common substrates are corrugated cardboard shipping boxes and HDPE containers for many markets such as case/pallet labeling, food, and health & beauty to name a few.

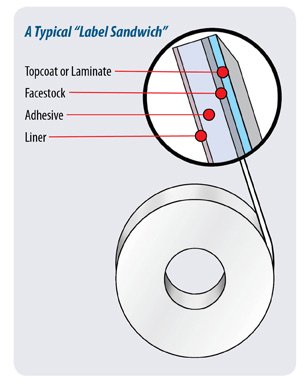

A pressure-sensitive label, or self-adhesive label, is made up of three layers: a face stock, an adhesive and a release liner. We refer to this as the "label sandwich." When a label is manufactured, these three components are sandwiched together to create a label material that can be printed on, laminated, die-cut, and finally peeled off and applied to your product.

A pressure-sensitive label, or self-adhesive label, is made up of three layers: a face stock, an adhesive and a release liner. We refer to this as the "label sandwich." When a label is manufactured, these three components are sandwiched together to create a label material that can be printed on, laminated, die-cut, and finally peeled off and applied to your product.

The facestock is the main part of the label. The material could be paper or film.The adhesive is what makes the label stick to the surface of the product or packaging. Pressure-sensitive adhesive forms a bond when pressure is applied to marry the adhesive with the substrate. The liner is the paper or film that makes up the backing web material.

Check out more information on what is a pressure sensitive label.

The right facestock material must be used to match the application to ensure good adhesion, weather resistance and legibility. Each facestock features certain characteristics for superior performance in specific work environments.

Here are some basic questions you will have to consider for selecting the proper face stock and adhesive combination for the best fit of your label application.

- What is the substrate the label will be applied to?

- What is the labeling environment?

- What is the temperature range for the product?

Paper The most common and economical type of facestock, paper is used for many simple indoor applications. Paper labels are made of paper. The color, thicknesses, and coatings of paper substrates can vary, but the base layer is still composed of the same raw material.Think short-term labeling.

Plastics BOPP films, PET films and vinyl films that provide greater strength, stiffness, transparency, and resistance to tearing. The flexibility and durability of film label materials allows them to conform and fit about the shape of your product container. Film labels are made from films (like plastic), making them a more durable and flexible material than paper. Designed for longer-lasting applications.