We have two exciting label materials called Transthin 375 and Transthin 400 for making your thermal transfer labels more efficient and economical.

Our Transthin materials are blank thermal-transfer label components that features both a thinner facesheet and a thinner release liner so there are more labels per same diameter roll.

Given the popularity of our high-yield thermal label material offering we are adding a new, and very competitively priced, Transthin 375 product to our portfolio to enhance our existing Transthin 400 material product line.

.jpg?width=227&name=Transthin%20375%20labels%20with%20text%20(002).jpg)

The Transthin 375 offers optimized economics through the development of a densified facestock, but with a versatile all-purpose rubber-based adhesive, and a highly densified glassine liner for improved web strength and stability.

The facesheet is just 2.5 mils thick but still retains the excellent dispensing characteristics required for successful print-apply applications. The release liner is just 1.7 mils thick but also retains the strength needed for the tension of the rewind reel on a typical label printer applicator.

We offer stock labels for 8” OD rolls for printers and 12” OD rolls for printer-applicators on our Go-Label.com site. Check out the details and prices:

• Product Code L-6541 for 8” OD Rolls

http://www.go-label.com/4_x_6_Transthin_375_Labels_8_inch_roll_p/l-6541.htm

• Product Code L-6540 for 12” OD Rolls

http://www.go-label.com/4_x_6_Transthin_375_Labels_p/l-6540.htm

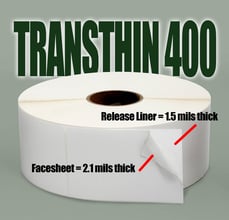

Our complimentary product called Transthin 400 uses a versatile all-temperature adhesive developed to provide good room temperature performance and excellent cold temperature performance. Because of its cold-temperature properties and good adhesion to corrugated cardboard and plastic packaging, the adhesive is an ideal adhesive for warehouse applications.

Our complimentary product called Transthin 400 uses a versatile all-temperature adhesive developed to provide good room temperature performance and excellent cold temperature performance. Because of its cold-temperature properties and good adhesion to corrugated cardboard and plastic packaging, the adhesive is an ideal adhesive for warehouse applications.

The facesheet is just 2.1 mils thick but still retains the excellent dispensing characteristics required for successful print-apply application. The release liner is just 1.5 mils thick but also retains the strength needed for the tension of the rewind reel on a typical label printer applicator.

We offer stock labels for 8” OD rolls for printers and 12” OD rolls for printer-applicators on our Go-Label.com site. Check out the details and prices:

• Product Code L-6528 for 8” OD Rolls

http://www.go-label.com/4_x_2_Transthin_400_Labels_p/l-6528.htm

• Product Code L-6529 for 8” OD Rolls

http://www.go-label.com/4_x_6_Transthin_400_Labels_8_Roll_p/l-6529.htm

• Product Code for 12” OD Rolls

http://www.go-label.com/4_x_6_Transthin_400_Labels_p/l-6527.htm

Compare an 8” OD roll for standard thermal transfer labels versus an 8" roll of Transthin:

- Standard 8” OD 4 x 6: 1,000 labels per roll with 4,000 labels per case.

- Transthin 8” OD 4 x 6: 1,500 labels per roll with 6,000 labels per case.

50% MORE: 500 labels per roll w/ 2,000 labels per case.

- 50% MORE Labels Per Roll

- 50% MORE Labels Per Box

- Lower Freight Costs

- Reduced Inventory Space

- Yield improvement applicable to most environmental scorecards.

- Available in 12” OD for automated applicators.

Transthin materials are designed to work with both stand-alone printers and printer-applicators.

Zebra, Sato and Datamax desktop printers handle the 8” OD finished rolls whereas our print-apply applicators handle the 12” OD finished rolls.

Label printer-applicators are the most efficient way to print variable data labels, like shipping labels, and apply them accurately on passing cartons and packages. But sooner or later you will have to shut down the line to change the empty label or ribbon rolls on each of your systems. A good operator can do that in a few minutes or even faster, but unless you have redundant systems that enable zero-down-time, you have to stop your production.

Label printer-applicators are the most efficient way to print variable data labels, like shipping labels, and apply them accurately on passing cartons and packages. But sooner or later you will have to shut down the line to change the empty label or ribbon rolls on each of your systems. A good operator can do that in a few minutes or even faster, but unless you have redundant systems that enable zero-down-time, you have to stop your production.