Where do I start??

No one ever really thinks about labels (unless you are a label person like me!) Labels exist on products to convey information. Perhaps you have come across labels when shopping that either entice you to buy a product or confuse you about just what it is. Some labels work better than others. It's all in the design.

There isn't one perfect label design that fits everything, but a well-designed label hits several key points:

Clear communication: It effectively conveys the product information, including brand, name, and key features. Think easy-to-read fonts and clear hierarchy in what info is most important.

The primary function of a label is to accurately represent the product it is attached to. It is crucial to clearly convey what the product is, its composition, and the quantity contained within. Imagine the confusion if someone mistook a bottle of blue window cleaner for raspberry fruit punch! It is essential to make it effortless for consumers to identify the product and access any vital information about it.

This becomes even more critical when dealing with chemical or pharmaceutical products. In urgent situations, medical professionals or emergency responders require precise and concise details about the product they are handling.

To address this need, these types of products often utilize specialized extended text labels. These labels provide a comprehensive amount of information readily available alongside the medicine or chemical product.

Visually appealing: Product labels often are used to sell a product from the store shelf. It catches the consumer's eye with a design that reflects the brand personality. This could be bright colors for a playful product or a sleek design for something more sophisticated.

Brands strategically utilize color and design to stand out from their competitors on the store shelf. Consider the iconic associations we make with certain colors and brands - Coca-Cola with red, Tide with orange, and John Deere with green.

Choose a color scheme and style that aligns with your brand identity. Your label can feature vibrant photos or intricate illustrations in a variety of colors. Incorporating innovative label materials like metallic films, fluorescent colors, and tactile laminations can elevate your product's visual appeal and make it unforgettable.

Choose a color scheme and style that aligns with your brand identity. Your label can feature vibrant photos or intricate illustrations in a variety of colors. Incorporating innovative label materials like metallic films, fluorescent colors, and tactile laminations can elevate your product's visual appeal and make it unforgettable.

Consumers often make decisions based on visual cues, so make sure your label catches their eye before they commit to a brand.

Choose a font style that is easily legible from afar and incorporate your logo to firmly establish your brand identity.

Functional: The size and shape of the label have to fit the product and the material has to be appropriate for the environment it will be in (e.g., waterproof for a beverage).

Cutting-edge label materials now encompass freezer-grade media that securely sticks in subzero conditions, specialized laminations resistant to chemicals to preserve label clarity, waterproof BOPP vinyl materials tailored for beverages, and robust durable label materials designed for outdoor or harsh settings.

Here's how these come together:

So now that you have the basics of a label, what else do I need to think about? This is where the artistic design part of the label comes in.

Consider the product: Food carries a distinct emotional resonance compared to, for example, a box of screws. What specific vibe do you aim to evoke with your label's appearance? Should it exude deliciousness or industrial functionality? Will it bring joy or simplify life? How do you want your customers to feel when they see it? Or does their emotional response even matter in the grand scheme of things?

A jar of jam might use a cute, colorful label with a handwritten font, while a bottle of high-end olive oil might have a more minimalist design with a focus on clean lines and earthy tones.Your new beer could embrace a lighthearted and witty persona, while a fresh laundry detergent exudes power and purity.

Think about the target audience: Consider the intended person who will be reading the label: Are you targeting a construction worker who values product reliability and durability, requiring the label to remain intact for an extended period?

Think about the target audience: Consider the intended person who will be reading the label: Are you targeting a construction worker who values product reliability and durability, requiring the label to remain intact for an extended period?

Or perhaps a no-nonsense nurse in need of critical dosage information for a new medicine? A label for baby food should be clear, informative, and trustworthy, while a label for a new energy drink might be more edgy and attention-grabbing.

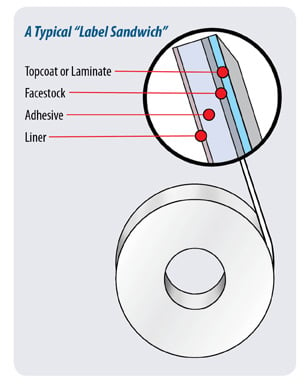

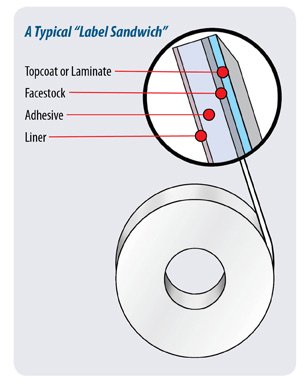

A pressure-sensitive label, or self-adhesive label, is made up of three layers: a face stock, an adhesive and a release liner. We refer to this as the "label sandwich." When a label is manufactured, these three components are sandwiched together to create a label material that can be printed on, laminated, die-cut, and finally peeled off and applied to your product.

A pressure-sensitive label, or self-adhesive label, is made up of three layers: a face stock, an adhesive and a release liner. We refer to this as the "label sandwich." When a label is manufactured, these three components are sandwiched together to create a label material that can be printed on, laminated, die-cut, and finally peeled off and applied to your product.