Our world is filled with many complex and complicated products, some of which can be dangerous if handled incorrectly.

And there are times when a product has to have emergency information available to users and first-responders.

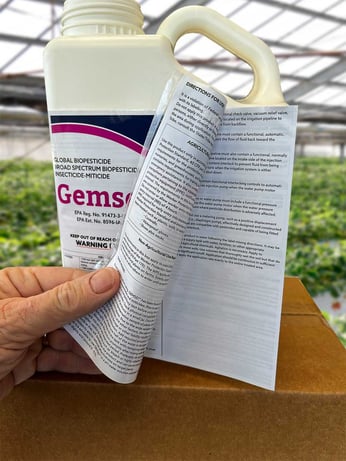

This is where a label called an Extended Text Label comes into play. Extended Content Labels (ECLs) are a family of labels designed to increase packaging space to convey in-depth information. If you've ever seen a bottle or a package with a label that folds or pops out, then you've seen at least one type of Extended Content Label.

ECLs are labels made up of multiple panels attached directly to the package that either unfold or unroll to reveal necessary information, such as regulatory requirements, multi-lingual text, promotions, cautionary messages, and much more.

While traditional labels are printed on one side of a piece of material, ECLs will give you more space for product information like ingredients and instructions and can free space up on the front of your label for branding and essential product information.

These labels are usually produced with a hinged format that opens to reveal additional panels that can even fold out additional pages. When you have a lot to say, these pages can contain all your information relevant to your product or business.

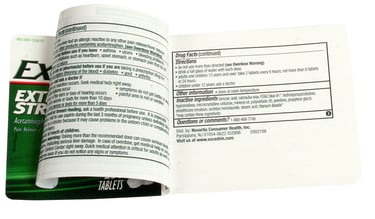

ECLs are perfect for communicating data in multiple languages or meet the needs of specific industry requirements like health warnings, application instructions, or warranty information.These types of labels appear in retail packaging, software product labeling, drug facts information, MSDS information, on personal care products or supplements, and food or beverage nutritional fact information.

Also known as multi-ply labels, peel-back or resealable labels, booklet labels and fold-out labels, they combine a Pressure Sensitive Label and a folded or bound outsert that resembles a printed booklet. There is usually a thin strip of clear laminate that has a removable adhesive that allows the booklet to be held closed when applied, opened when needed, and re-closed when done.

Here is a quick video of an extended text label being printed at Weber packaging Solutions.

Watching the video you can see the printed information, usually printed by an offset printer, is fed into the label press where it is sandwiched between the label of label material and the protective laminate covering. It is then die-cut and wound on rolls for use on a label applicator at the manufacturer's facility.

This kind of label becomes important when packaging profiles are small and there is not enough room on labels for your message. Extended Content Labels provide space for more graphics and copy through the use of multiple pages. They are all engineered to do the same thing — increase the amount of space available for text and graphics. Expanded content labels contain more space for information than ordinary labels.

Extended content labels allow the outer label to be decorative and market the product and brand, while the internal layers contain vital information to comply with regulations and inform the consumer about necessary product details.

Extended content labels allow the outer label to be decorative and market the product and brand, while the internal layers contain vital information to comply with regulations and inform the consumer about necessary product details.

The most common applications are for pharmaceutical products, clinical trials, nutraceuticals, chemicals, pesticides, weed control products, lubricants, cosmetics and more!

- Brand label. If only brand is used on package of a product, this is called brand label. Brand itself is expressed in label. It plays an important role in labelling as it gives information about the brand. It can be removable or non-removable

- Grade Label. Some product have given grade label. It describes the aspect and feature of the product.

- Descriptive label. Descriptive label give information about the feature, using instruction, handling, security. It specifies product usage.

- Informative label

Additional label content that is often completed with extended content, booklet labels or smooth peel labels are the following:

Additional label content that is often completed with extended content, booklet labels or smooth peel labels are the following:

- Instructions

- Multiple languages

- In-store coupons

- Rebate details

- Game and sweepstake pieces

- Recipes and ingredients

- Promo items

- Informational takeaways

- Cross-promotional products

This label offers endless options for customization and meets multi-lingual, regulatory, and marketing objectives. Manufacturing will love it too, there is no adjustment to application equipment required to run this label. The transition is seamless.

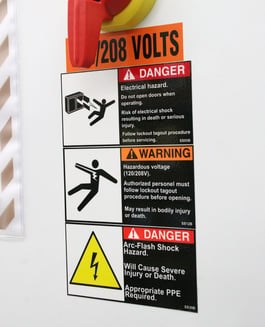

What do automotive parts, power tools, fire extinguishers, electronic components and chemical containers have in common?

What do automotive parts, power tools, fire extinguishers, electronic components and chemical containers have in common? When it comes to durable goods, labels are for life. These labels can include words, pictures, or both, whatever is necessary to identify the contents and their importance. Labels help customers use and maintain their cars, power tools and appliances. And by delivering directions and critical warnings, labels keep people safe.

When it comes to durable goods, labels are for life. These labels can include words, pictures, or both, whatever is necessary to identify the contents and their importance. Labels help customers use and maintain their cars, power tools and appliances. And by delivering directions and critical warnings, labels keep people safe.

Swanson was approached by one of their customers about a new packaging configuration for two of their largest framing square sizes. Typically, the labeling for these items include a large glossy tagstock material that is stapled or glued together, sometimes with an instructional “blue book” contained within. Because of the odd shape, this is all prepared by hand.

Swanson was approached by one of their customers about a new packaging configuration for two of their largest framing square sizes. Typically, the labeling for these items include a large glossy tagstock material that is stapled or glued together, sometimes with an instructional “blue book” contained within. Because of the odd shape, this is all prepared by hand.  The primary requirement for this label was that it needed to be removable without leaving any residue behind on the high-quality CNC-machined aluminum framing squares that would frustrate the end user. After all, the preferred location of this new label was directly on top of etched distance and angle markings, essential for the use of the product.

The primary requirement for this label was that it needed to be removable without leaving any residue behind on the high-quality CNC-machined aluminum framing squares that would frustrate the end user. After all, the preferred location of this new label was directly on top of etched distance and angle markings, essential for the use of the product.  Next, they asked Weber to find a way to automate the labeling process. The idea was to place a triangle-shaped label on the corner of the framing squares, or a triangle-on-a-triangle. The framing squares have an extended base, or bevel, which allows them to nicely rest along side the length of a piece of lumber and be slid up and down to trace lines for cutting.

Next, they asked Weber to find a way to automate the labeling process. The idea was to place a triangle-shaped label on the corner of the framing squares, or a triangle-on-a-triangle. The framing squares have an extended base, or bevel, which allows them to nicely rest along side the length of a piece of lumber and be slid up and down to trace lines for cutting.

RFID (Radio Frequency Identification) technology has been around for many years. It first caught on in retail and logistics as a natural fit. Items with RFID labels, also referred to as Smart Labels or Intelligent Labels, can be tracked and identified efficiently through every stage of the supply chain, from purchasing to shipping to delivery.

RFID (Radio Frequency Identification) technology has been around for many years. It first caught on in retail and logistics as a natural fit. Items with RFID labels, also referred to as Smart Labels or Intelligent Labels, can be tracked and identified efficiently through every stage of the supply chain, from purchasing to shipping to delivery. Today, pharmaceutical companies are also recognizing the benefits of RFID labels, and for very good reasons. In pharma, RFID labels help to manage inventory, increase operational efficiencies, remain in compliance with governmental regulation, and ensure the wellbeing of patients and consumers. RFID labels also enable itemizing and sorting of stock to ensure quality and prevent waste.

Today, pharmaceutical companies are also recognizing the benefits of RFID labels, and for very good reasons. In pharma, RFID labels help to manage inventory, increase operational efficiencies, remain in compliance with governmental regulation, and ensure the wellbeing of patients and consumers. RFID labels also enable itemizing and sorting of stock to ensure quality and prevent waste.  It is critical to provide the right drug and of course, one that's free of tampering. RFID not only ensures integrity, it delivers strong counterfeiting deterrence as the label itself could be used to authenticate the pharmaceutical product and tamper evidence.

It is critical to provide the right drug and of course, one that's free of tampering. RFID not only ensures integrity, it delivers strong counterfeiting deterrence as the label itself could be used to authenticate the pharmaceutical product and tamper evidence.  In North America, 250 million blood bag labels are used on average every year, and demand is expected to continue to grow significantly. Giving blood is a simple, straightforward process and donating a pint of blood typically takes less than 12 minutes.

In North America, 250 million blood bag labels are used on average every year, and demand is expected to continue to grow significantly. Giving blood is a simple, straightforward process and donating a pint of blood typically takes less than 12 minutes.  These labels are:

These labels are: