Whether you're new to label automation or updating old systems, consider these key points. With many print-apply labeling machines available, most perform well, but differences in features and construction can affect uptime, maintenance, and longevity.

Here are 6 Pro Tips to Get You Started

Durability

The level of activity your print-apply system experiences can vary greatly depending on your product type and production line. New automation companies might label 10-20 items per hour, while a distribution center could label a package every few seconds. In both scenarios, durability is critical. What if the machine breaks down? Can you afford to have your production line stopped while repairs are made? This could lead to a bottleneck, delaying product shipments. While a zero-downtime system with a backup printer-applicator is an option, it can be costly.

When selecting a new print-apply labeling system, look for those with a solid reputation for durability and maintenance. Remember, you get what you pay for. Opting for a less expensive system might save money initially but could lead to future headaches and expenses when replacements are needed sooner than expected.

- Consider systems constructed with robust materials like stainless steel and aluminum plate.

- Ensure all connections are safeguarded against damage or misuse.

- Are moving parts, such as applicator arms, protected to ensure operator and worker safety?

- Choose a print engine from a reputable manufacturer like Zebra or Sato, featuring the latest advancements. These models seamlessly integrate with your online systems for loading label formats and tracking jobs.

Maintenance

Much like your car, your labeling system requires regular maintenance to keep it in peak condition. With heavy use, parts can wear out. Ensure that rollers, drive belts, and other moving components are built to last and are easily accessible for replacement if needed. You should be able to perform basic maintenance with simple tools without dismantling the entire system.

It's crucial that the manufacturer can provide maintenance parts swiftly and conveniently, ideally through online ordering, and at a reasonable cost. Avoid using aftermarket parts, as they may be of lower quality and could harm your applicator. Ensure the manufacturer offers comprehensive technical support for any significant issues you might encounter. Having a service technician available for on-site visits is also a key factor to consider.

Beyond just checking the warranty of the equipment you're considering, investigate the experiences of actual customers or seek out online case studies of these systems. A quick phone call could prevent a lot of future hassles. Look for a provider with a solid track record of satisfied customers and reliable equipment over the long term.

Easy-To-Use

While they may appear straightforward, print-apply systems are complex machines. They must synchronize the printing of a label format, dispense it onto an applicator, and apply the label precisely at the right moment, sometimes with varying spacing or orientation. Ideally, you want a controller that manages all the heavy lifting behind the scenes, so the operator doesn't need to be an expert.

Seek out a system with a large touchscreen that guides you through straightforward instructions or menus to access what you need. Many systems require minimal operator input to get the printer-applicator running smoothly or to make minor adjustments. Some of the latest systems offer troubleshooting information, animations, and other valuable insights about the equipment, such as event logs and equipment status. It's always preferable if the operator can resolve an issue without needing a service call or causing production downtime.

Flexible Design

Today, printer-applicators are being designed with modular construction, allowing them to be tailored to the unique needs of your application. These modular components simplify troubleshooting and replacement when necessary.

Look for a manufacturer that offers the right applicator type for your labeling needs. You might require two labels on adjacent carton sides (twin-tamp) or a wrap-around corner label with identical information on each panel (corner-wrap). Labels can also be applied to pallets from a distance, on both the bottom and top of a package, or even wrapped around a clam shell in three sections, which is common in bakeries.

A standard print-apply system should offer configurations like wipe-on, blow-on, or tamp-on, with the best choice depending on your specific product or application.

A common challenge with print-apply systems is the wear on the print head over time. To address this, choose a brand that incorporates powered unwinders and rewinders for label transport. This ensures consistent pressure, avoiding the jerky movements that occur as the applicator print engine advances the label material. Smooth, consistent label movement is crucial for extending the life of the print head.

Cost Effective

When assessing the long-term cost of your print-apply system, there are a few key considerations. Many tamp-blow and blow-on applicators rely on compressed air to move the label from the tamp pad to the product. This process involves swiftly switching from a vacuum on the tamp pad (to hold the label) to a burst of air that applies it. Some systems can be inefficient, with air leaks around the filter. Opt for a system that employs a modulated vacuum, using integrated sensors to measure pressure and minimize air consumption by using only what's necessary.

Systems that substitute small fans for compressed air still need electricity, can get clogged, or become unreliable in tough conditions, and may not always perform as expected.

Seek out manufacturers whose systems don't require scheduled maintenance. This approach reduces downtime and avoids unnecessary parts replacement. Choose a well-constructed print-apply system that operates smoothly without needing constant oversight or frequent downtime.

Safety

Employee safety is a top priority for every company. Print-apply systems, with their numerous moving parts and potential pinch-points, pose a risk of injury from the moving applicator arm. It's essential to choose a system designed with safety in mind, ensuring operators are protected from harm.

Look for systems that comply with EN 415-10 safety standards and include an emergency stop function for situations requiring more force than deemed safe by these standards. Protective guards should be installed to reduce exposure to moving parts.

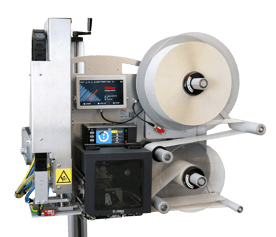

Weber Model 4050B Label Printer Applicators

At Weber Packaging Solutions, engineers took all these factors into account when designing the new Model 4050B Label Printer Applicator, ensuring a reliable and efficient solution for your labeling needs.

The 4050B print-apply system boasts a modular design that can be tailored to any application. It accommodates print engines from leading manufacturers and is available in three high-speed models with high-resolution printing. Each model's modular design ensures quick in-field repairs, maximizing uptime.

To suit various production environments, the system can be configured for right-or left-hand use. The stepper-driven stroke is adjustable for different labeling needs, and numerous I/O options allow interfacing with various external devices. The motorized label unwinder reduces wear on the print engine and ensures smooth feeding of the supply roll.

Model 4050B Overview

Model 4050B-EL- This electric tamp-blow print-apply system uses an electric linear actuator for higher speed and reduced weight. It can apply labels to the sides, tops, or bottoms of packages.

- This electric tamp-blow print-apply system uses an electric rotary swing arm for higher speed and reduced weight. It can apply labels to the front or rear of packages.

Both the 4050B-EL and 4050B-ES use air only as a vacuum to hold and blow the label onto the product, providing a non-contact labeling method that is quick and efficient.

Model 4050B-EB- This electric wipe-on print-apply system uses a high-speed transfer belt driven by electricity, requiring no air. It can apply labels to the sides, tops, or bottoms of packages.

The 4050B features a 7” Touch Display with rugged aluminum construction, single-key calibration, easy access to labeling settings, productivity status, and maintenance alerts.

Additionally, the Model 4050B meets all EN415-10 safety requirements. Weber’s quality assurance program monitors parts and assembly during production. Designed for 24/7 operation, the system is a compact robust label printer applicator that can meet all your labeling needs.

For more information on the Weber Model 4050 label printer applicator, go to info.weberpackaging.com/model-4050 or email us at info@weberpackaging.com.

Choose a color scheme and style that aligns with your brand identity. Your label can feature vibrant photos or intricate illustrations in a variety of colors. Incorporating innovative label materials like metallic films, fluorescent colors, and tactile laminations can elevate your product's visual appeal and make it unforgettable.

Choose a color scheme and style that aligns with your brand identity. Your label can feature vibrant photos or intricate illustrations in a variety of colors. Incorporating innovative label materials like metallic films, fluorescent colors, and tactile laminations can elevate your product's visual appeal and make it unforgettable.

Think about the target audience

Think about the target audience

Could there be a better alternative to the constant downtime and maintenance? Enter Weber's Markoprint thermal inkjet systems, a revolutionary type of inkjet coder that utilizes HP ink cartridges instead of bulky ink tanks found in CIJ systems. These Markoprint coders come in various configurations, from single-head, stand-alone coders for simple date code applications to multi-head systems for coding both sides of a carton and larger prints.

Could there be a better alternative to the constant downtime and maintenance? Enter Weber's Markoprint thermal inkjet systems, a revolutionary type of inkjet coder that utilizes HP ink cartridges instead of bulky ink tanks found in CIJ systems. These Markoprint coders come in various configurations, from single-head, stand-alone coders for simple date code applications to multi-head systems for coding both sides of a carton and larger prints.