Weber has been building label printer applicators for over 25 years and has thousands of ultra-reliable systems happily churning out labeled packages around the world. Our Models 5100, 5200, and 5300 print-apply systems have evolved over the years from simple to complex, with a variety of label application arms for just about any production line. You wouldn't believe some of the things we are successfully putting labels on.

Weber has been building label printer applicators for over 25 years and has thousands of ultra-reliable systems happily churning out labeled packages around the world. Our Models 5100, 5200, and 5300 print-apply systems have evolved over the years from simple to complex, with a variety of label application arms for just about any production line. You wouldn't believe some of the things we are successfully putting labels on.

But when our Engineering Team sat down to devise the next generation of Weber printer applicators, they decided to address the long wish-list of features suggested by our customers. (Most made sense, though asking for tail fins might have been asking too much.) We wanted to build the most reliable print-apply system available with efforts to reduce maintenance and running costs, and keep the system user-friendly and easy to operate.

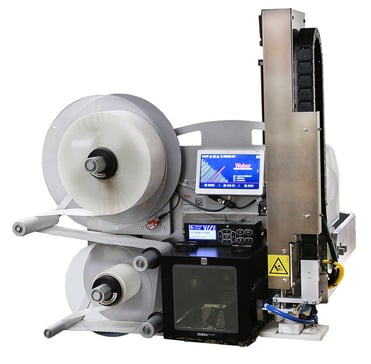

After a few years of design, testing and implementation, Weber is now pleased to roll out our new Model 4050E-LK tamp-blow printer applicator. The unit is manufactured in the USA at our headquarters in Arlington Heights, IL. It uses a modular base system design for fast assembly, minimal maintenance, and reduced downtime. The 4050E-LK allows the customers to provide a non-contact method of labelling products quickly and efficiently on their production line.

After a few years of design, testing and implementation, Weber is now pleased to roll out our new Model 4050E-LK tamp-blow printer applicator. The unit is manufactured in the USA at our headquarters in Arlington Heights, IL. It uses a modular base system design for fast assembly, minimal maintenance, and reduced downtime. The 4050E-LK allows the customers to provide a non-contact method of labelling products quickly and efficiently on their production line.

The applicator uses a modulated vacuum to reduce air consumption, using over 80% less air than previous models. And while other brands are using air-free solutions via fans, we saw that the convenience of using fans falters from the cost of maintenance and downtime. The 4050E-LK labeler has a clear cover over the pneumatic system which makes it easy to view and access during operation.

The Model 4050E-LK also features a powered label unwind and rewind to reduce print engine wear and provide smooth feeding of the supply roll while not creating as much pull friction on the print head. Anyone who uses a print apply system knows that the number one problem is the constant tugging of the labels from the supply roll that can actually wear grooves in the rollers and wear down the print head from continuous use. The powered unwind/rewinders all but eliminate that wear.

One of the most noticeable features of the 4050E-LK is the 7” color touch display that allows easy access to all parameters. A tap of the screen brings up all the settings and adjustments necessary to run the 4050E-LK. It allows you to view error diagnostics and logs, along with productivity and maintenance status.

One of the most noticeable features of the 4050E-LK is the 7” color touch display that allows easy access to all parameters. A tap of the screen brings up all the settings and adjustments necessary to run the 4050E-LK. It allows you to view error diagnostics and logs, along with productivity and maintenance status.

Another one of the new features is the vast amount of I/O's mounted on the back of the system for easy access. USB, network cabling and an array of sensors can be connected with even more optional flexibility available.

The applicator is available in multiple tamp lengths and pad sizes, with more labeling options coming available later in the year. The unit is compatible with all Zebra and SATO print engines.

Now is the time to contact your local Weber sales rep for complete information and pricing on the Model 4050E-LK. Visit our web site or contact me at info@weberpackaging.com.