Unveiling the Remarkable History of Pressure-Sensitive Labels

Unveiling the Remarkable History of Pressure-Sensitive Labels

Have you ever paused to consider the small yet indispensable labels on the products you use daily? From food and beverages to cosmetics and household goods, pressure-sensitive labels (PSLs) have become a cornerstone of modern packaging. But have you ever wondered about their origins or how they came to be? Today, we’ll take a deep dive into the fascinating history of pressure-sensitive labels, illuminating the unsung heroes that enhance our shopping experience by providing crucial information and making products more engaging.

The Genesis of Pressure-Sensitive Labels

The journey of pressure-sensitive adhesives (PSA) began in the early 20th century and marked a breakthrough in adhesive technology. Unlike traditional adhesives that required heat, water, or solvents, PSA allowed materials to adhere simply by applying pressure. This new adhesive innovation created the foundation for labels that could easily bond to surfaces while being repositionable or removable.

It all started with adhesive-coated paper, which enabled labels to be affixed to various surfaces. Initially, applying this adhesive was a labor-intensive process, done manually. However, in 1935, everything changed with the advent of a revolutionary machine that automated the application of adhesive, transforming the labeling industry.

The Breakthrough: R. Stanton Avery’s Vision

A pivotal moment in PSL history came in 1935 with R. Stanton Avery’s invention of the first pressure-sensitive label. Avery’s innovation centered around a self-adhesive label that was not only easier to apply but also more efficient, particularly for packaging and shipping industries. He introduced a permanent adhesive combined with a release paper backing, which marked the birth of the modern pressure-sensitive label. This invention was groundbreaking because it enabled businesses to print directly on the label and apply it effortlessly, without the need for heat or water.

The Revolution: Entering the Era of Pressure-Sensitive Technology

The 1940s ushered in an exciting new era for the labeling industry with the introduction of pressure-sensitive technology. Instead of relying on traditional methods like wet glue or heat, these labels adhered simply through pressure, making them easier to apply and reposition. The new technology quickly gained traction, offering greater convenience and flexibility.

In 1944, Avery founded the Avery Adhesive Company, which later evolved into Avery Dennison. This company played a crucial role in commercializing PSLs and driving their widespread adoption across industries. By the 1950s, pressure-sensitive labels had gained significant popularity, particularly in the food, pharmaceutical, and consumer goods sectors.

Advancing Materials and Expanding Applications

As the technology behind pressure-sensitive adhesives evolved, so did the materials and applications of PSLs. The 1960s saw major strides in self-adhesive materials, including the first barcoded labels, which were transformative for retail and inventory management.

Throughout the 1970s, synthetic materials like polypropylene and polyester began replacing paper as the primary substrates. These new materials were more durable, resistant to moisture, and better suited for use in challenging environments like cold storage or industrial applications. This opened up new possibilities for labeling a broader range of products, from refrigerated items to pharmaceuticals and industrial equipment.

The 1990s marked a further breakthrough with the rise of digital printing technologies. This advancement allowed companies to print PSLs on demand, in smaller quantities, and with greater customization. It also sparked a wave of creative possibilities in label design, particularly for consumer products like cosmetics, beverages, and wines.

The Modern Era: Sustainability and Innovation

One of the most notable developments in recent years is the growing focus on sustainability within the PSL industry. With an increasing demand for eco-friendly solutions, manufacturers have developed biodegradable and recyclable materials, including liners, that reduce waste and environmental impact.

Moreover, PSLs have become a popular medium for innovative designs and interactive features. From scratch-and-sniff labels to heat-sensitive designs that change color, PSLs now offer more than just information—they engage and surprise consumers.

The technology behind PSLs continues to advance with smart labeling, incorporating elements like RFID (Radio Frequency Identification) for enhanced product tracking and security. Additionally, tamper-evident features and specialized adhesives have made these labels even more versatile, ensuring their use across various sectors like logistics, healthcare, and food packaging.

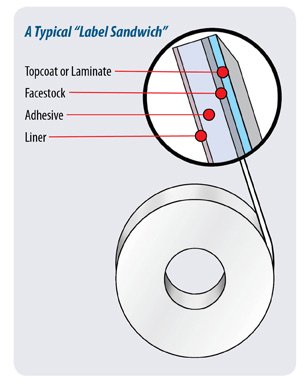

A pressure-sensitive label, or self-adhesive label, is made up of three layers: a face stock, an adhesive and a release liner. We refer to this as the "label sandwich." When a label is manufactured, these three components are sandwiched together to create a label material that can be printed on, laminated, die-cut, and finally peeled off and applied to your product.

A pressure-sensitive label, or self-adhesive label, is made up of three layers: a face stock, an adhesive and a release liner. We refer to this as the "label sandwich." When a label is manufactured, these three components are sandwiched together to create a label material that can be printed on, laminated, die-cut, and finally peeled off and applied to your product.

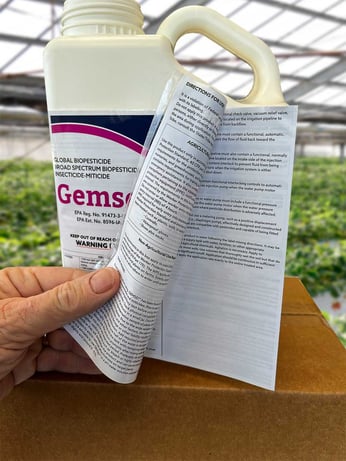

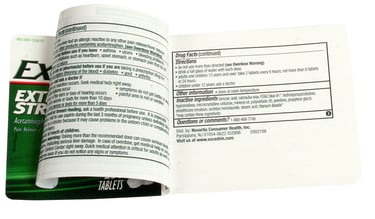

Additional label content that is often completed with extended content, booklet labels or smooth peel labels are the following:

Additional label content that is often completed with extended content, booklet labels or smooth peel labels are the following: What do automotive parts, power tools, fire extinguishers, electronic components and chemical containers have in common?

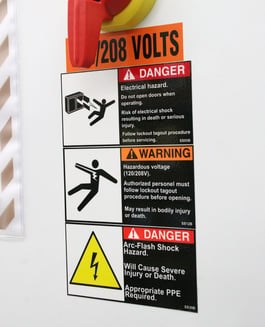

What do automotive parts, power tools, fire extinguishers, electronic components and chemical containers have in common? When it comes to durable goods, labels are for life. These labels can include words, pictures, or both, whatever is necessary to identify the contents and their importance. Labels help customers use and maintain their cars, power tools and appliances. And by delivering directions and critical warnings, labels keep people safe.

When it comes to durable goods, labels are for life. These labels can include words, pictures, or both, whatever is necessary to identify the contents and their importance. Labels help customers use and maintain their cars, power tools and appliances. And by delivering directions and critical warnings, labels keep people safe.

Swanson was approached by one of their customers about a new packaging configuration for two of their largest framing square sizes. Typically, the labeling for these items include a large glossy tagstock material that is stapled or glued together, sometimes with an instructional “blue book” contained within. Because of the odd shape, this is all prepared by hand.

Swanson was approached by one of their customers about a new packaging configuration for two of their largest framing square sizes. Typically, the labeling for these items include a large glossy tagstock material that is stapled or glued together, sometimes with an instructional “blue book” contained within. Because of the odd shape, this is all prepared by hand.  The primary requirement for this label was that it needed to be removable without leaving any residue behind on the high-quality CNC-machined aluminum framing squares that would frustrate the end user. After all, the preferred location of this new label was directly on top of etched distance and angle markings, essential for the use of the product.

The primary requirement for this label was that it needed to be removable without leaving any residue behind on the high-quality CNC-machined aluminum framing squares that would frustrate the end user. After all, the preferred location of this new label was directly on top of etched distance and angle markings, essential for the use of the product.  Next, they asked Weber to find a way to automate the labeling process. The idea was to place a triangle-shaped label on the corner of the framing squares, or a triangle-on-a-triangle. The framing squares have an extended base, or bevel, which allows them to nicely rest along side the length of a piece of lumber and be slid up and down to trace lines for cutting.

Next, they asked Weber to find a way to automate the labeling process. The idea was to place a triangle-shaped label on the corner of the framing squares, or a triangle-on-a-triangle. The framing squares have an extended base, or bevel, which allows them to nicely rest along side the length of a piece of lumber and be slid up and down to trace lines for cutting.