|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

Topics: Label Applicators, Labels, Labeling Systems, Trade Show, label printer applicators, Variable-height labeling, Label printer applicator, LA-2050

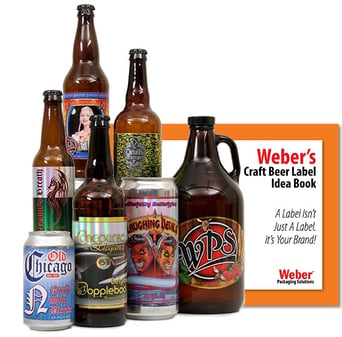

Is it time for a label redesign at your brewery? Or are you contemplating a new exotic small batch run and need some craft beer label ideas?

Is it time for a label redesign at your brewery? Or are you contemplating a new exotic small batch run and need some craft beer label ideas?

Now you can get some help by downloading Weber's new Craft Beer Label Idea eBook. This publication has information garnered from the industry that will help you make some decisions about your labeling process, including:

Weber has experience designing and printing labels for the craft beer industry and can help all brewers from start-ups to large mega corporations. Using th

e right materials and applying the labels correctly will make your brand stand out from the competition. Poorly printed craft beer labels, labels that don't stick when exposed to moisture, and labels that are applied crooked all make your product look bad. And with so many other craft brewers out there, you want to make a good impression with your audience of customers.

You can now order your limited run craft beer labels from Weber's Go-Label.com site! Choose from a wide range of materials and finishes to create a unique look for your brand. And the labels are steeply discounted as you buy more. Minimum order is only 1 roll of 500 labels! We can turn your order around in just 5 days after artwork approval. It's simple and easy to order. Use our Chat Live on Go-Label to ask our operator for more info.

Topics: Label Applicators, craft beer labels, beer labeling system, craft beer label ebook, label design

What is the best ribbon to use in my thermal-transfer label printer?

Good question.

Most people never stop to think about whether they are using the most efficient, cost-effective ribbon for their every-day labels. They just keep ordering the brand that came with their Zebra or Sato label printer.

But there have been many new advancements in ribbon technology that could help users save money on label costs and maintenance. So here are four good reasons to check and see if you are getting the best bang for your buck with your ribbons and how Weber's Go-Mark 100 ribbons might change your mind.

One: What are you labeling?

Most people that use thermal-transfer label printers from manufacturers like Zebra, Datamax and Sato are printing simple paper labels for bar code or shipping labels. These labels are mostly single use, applied usually to a shipping carton or envelope, and don't need to last more than a week or so. They get ripped off and throw away after the package arrives. Done.

Most people that use thermal-transfer label printers from manufacturers like Zebra, Datamax and Sato are printing simple paper labels for bar code or shipping labels. These labels are mostly single use, applied usually to a shipping carton or envelope, and don't need to last more than a week or so. They get ripped off and throw away after the package arrives. Done.

Barring any extreme handling or careless shipment, standard wax ribbons work just fine for shipping and bar code labels. Depending on the ribbon, you get a dark black transfer of the text or image onto plain paper labels that are fairly durable. But beware; some wax ribbons don't print dark enough or transfer the ink from the ribbon correctly, making the label hard to read. Buy quality wax ribbons from a good source.

Weber's Go-Mark 100 wax ribbons feature a rich blackness for basic label printing applications such as shipping and product identification labels. The new ribbons are compatible with both coated and uncoated label materials, working well with flood-coated color labels, too.

If you need a more durable print on your label, say for a label that will endure abrasion or needs to last more than a week, you can step up to a wax/resin formulation ribbon that will last longer. But the price increases, too. If you don't worry about harsh treatment or longevity, stick with simple wax ribbons.

Also, be sure to pick a ribbon that fits the size requirements of your label. Don't use a 4-inch wide ribbon if your label printing area is only 2 inches wide. You can use a less-expensive ribbon by selecting a ribbon just slightly wider than the label width. For example, if you have only a 2" wide label, use a 2.36" width ribbon instead of a 4.06" ribbon which is more money per roll. But remember, it is important that the ribbon be slightly wider than the label to protect the printhead.

Two: Print head maintenance

One of the inherent problems with thermal-transfer label printing is keeping the print head happy. Inside each printer is a heating device that transfers the ink from the ribbon to the label surface. Read this blog of ours about to see how that works.

The print head can get finicky when dirt and dust from the workplace (or just paper dust from the label roll) starts clogging it up. Your label will have areas of missing print indicating it's time for maintenance on the printer.

The print head can get finicky when dirt and dust from the workplace (or just paper dust from the label roll) starts clogging it up. Your label will have areas of missing print indicating it's time for maintenance on the printer.

And easy way to avoid this problem is to clean the print head after every ribbon change. But not many people want to take the time to open the print head and do the work.

The new Go-Mark 100 wax ribbons from Weber now come with a built-in Clean Start leader that automatically cleans your print head as you load each ribbon. It takes care of the dust and dirt while maintaining your printer every time you change ribbons. Simple. And no more missing print or stopping production to do housekeeping chores.

Topics: Printer Ribbons, Label Printers, Thermal-Transfer Ribbons, Go-Mark 100 Wax Ribbons

Posted by Chris Erbach

May 16, 2017 8:47:13 AM

What is thermal-transfer printing?

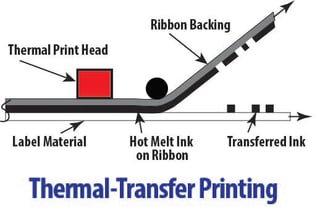

A thermal-transfer printer is a non-impact printer. With thermal-transfer printing, a thermal print head applies heat to a ribbon, which melts ink from the ribbon onto the label material to form the image. A typical thermal-transfer ribbon consists of three layers: the base material or ribbon backing, the hot melt ink, and the coating on the print side of the base material.

A thermal-transfer printer is a non-impact printer. With thermal-transfer printing, a thermal print head applies heat to a ribbon, which melts ink from the ribbon onto the label material to form the image. A typical thermal-transfer ribbon consists of three layers: the base material or ribbon backing, the hot melt ink, and the coating on the print side of the base material.

Thermal-transfer printers are everywhere – from desktop units & industrial tabletop units to automated print and apply labeling systems. Since different ribbons are made of various ink formulations, a thermal-transfer heat setting can be adjusted on the printer for the given ribbon/label stock combination. Zebra printers require ribbons wound with the ink side out referred to as coated side out (CSO). Datamax printers require ribbons wound with the ink side in referred to as coated side in (CSI). Sato printers can use either configuration.

How do you decide which ribbon type will produce optimal results and is best suited for your application? Label material and the application environment/requirements will play a major role in determining the proper ribbon. In thermal transfer printing, the printer, ribbon and substrate work together as a printing system.

Topics: Printer Ribbons, Label Printers, Thermal-Transfer Ribbons

Mission Impossible to Mission Accomplished!

We have all seen RFID labels and tags on products in stores. Usually they are on more expensive items that are small and are often targets of shoplifting. `

We have all seen RFID labels and tags on products in stores. Usually they are on more expensive items that are small and are often targets of shoplifting. `

When you check out, the cashier rubs the RFID tag on a deactivation device that kills or zeroes the encoding. This allows the customer to walk out the door without alarms going off at the door.

How many times has a cashier missed a tag of yours and you set off the alarm on your way out of a store? Awkward to say the least!

But there are other ways that RFID labels are being used in manufacturing and distribution these days.

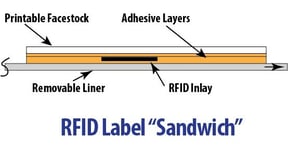

RFID (Radio Frequency Identification) is an automatic identification method that stores and remotely retrieves data via an RFID inlay embedded in a label or tag. The components of an RFID label include:

RFID (Radio Frequency Identification) is an automatic identification method that stores and remotely retrieves data via an RFID inlay embedded in a label or tag. The components of an RFID label include:

Here is an industrial application that came up recently. Weber had a customer that was having trouble with missing shipping containers and asked us to help with the project.

Texas-based Mission Foods, one of the world’s largest producers of corn flour & tortilla products, was losing thousands of returnable plastic trays annually. This resulted in millions of dollars lost in revenue each year.

Topics: RFID, Food Labels, Label Printers

You finally get that new label printer for your shipping department and you start reading the manual. You new printer is ideal for printing labels with bar codes and high-quality images. That's great. Hmmm... it prints in both thermal-transfer and direct thermal modes.

Topics: Label Printers