It's time to order a batch of labels for my new product. I need to get this label order right the first time so production goes smoothly. What information does my label printer need from me?

There are a lot of specs you need to give to your printing company when it's time to order new pressure-sensitive labels. These usually include:

- Label material

- Label adhesive

- Final label size

- Number of colors

- Special label features (like booklet, coupon, extended text, etc.)

- And the Unwind direction

What is the unwind direction?

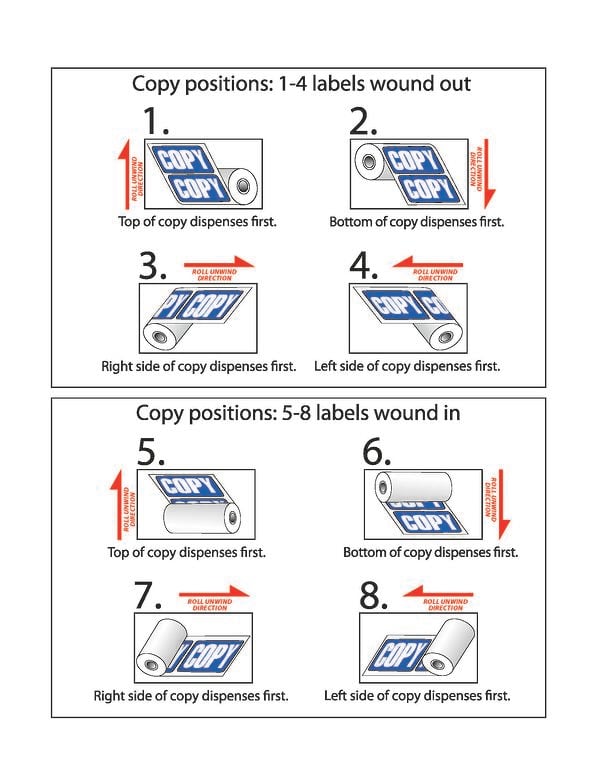

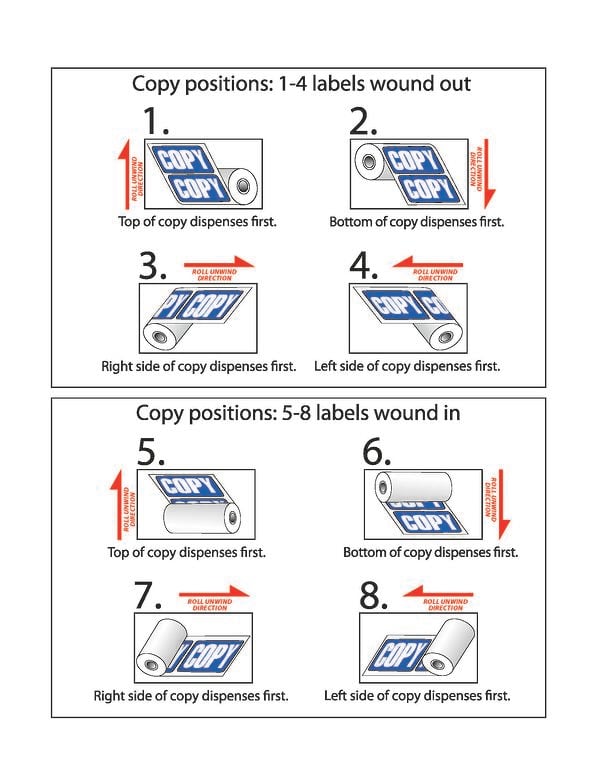

The unwind direction is the orientation of the label as it will feed out of a label printer or label applicator. There are eight different directions you could choose from for your unwind direction. Depending on whether you are applying them by hand or using automated machinery, this can be a critical factor.

If you are using a label applicator, make sure that you pick the correct orientation for your label to feed out onto your product. You don't want the label to be applied upside down! And some label applicators feed differently so be sure to check with your packaging team to make sure you order the labels with the right feed direction.

Why it matters

If your labels are to be fed out of a label printer or label applicator, then it is very likely that the label orientation is critical to the application. If you don't pick the correct unwind direction, you risk printing your barcode or other variable data in the wrong spot or even over your artwork. Selecting the correct direction also means you won't need to adjust your applicator because the labels are applying upside down!

Check out this handy guide to the various rewind directions.

Next time you are near your labeling operation, see if you can use this chart to figure out your current label orientation. Maybe you need to adjust it on your next order to improve labeling efficiency? If you are unsure or need help figuring it out, give us a call or email for more information.

The next deadline for GHS labeling compliance is less than a year away! Starting June 1st, 2015 all manufacturers and distributors of chemicals will be required to comply with the Globally Harmonized System of Classification.

The next deadline for GHS labeling compliance is less than a year away! Starting June 1st, 2015 all manufacturers and distributors of chemicals will be required to comply with the Globally Harmonized System of Classification.

A label printer-applicator is an automatic labeling system that has the ability to print variable information onto a pressure-sensitive label, then apply it to a container. Sometimes companies want to use a label that has the same pre-printed information such as a logo, company info, or background color, then add different information to the label depending on the product that it is being applied to. You will find these systems applying shipping labels, product information labels,

A label printer-applicator is an automatic labeling system that has the ability to print variable information onto a pressure-sensitive label, then apply it to a container. Sometimes companies want to use a label that has the same pre-printed information such as a logo, company info, or background color, then add different information to the label depending on the product that it is being applied to. You will find these systems applying shipping labels, product information labels,

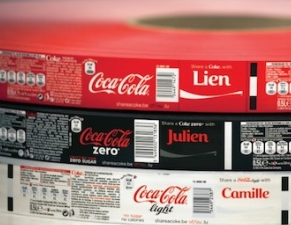

Share a Coke

Share a Coke

By now you've probably heard that OSHA is requiring updates to the Hazard Communication Standard label to comply with the Globally Harmonized System (GHS) label. As we've mentioned before, the

By now you've probably heard that OSHA is requiring updates to the Hazard Communication Standard label to comply with the Globally Harmonized System (GHS) label. As we've mentioned before, the If your manufacturing facility is like ours and you need GHS labels on small bottles around the plant, try what's worked for us. All of our small chemical bottles are labeled by our Safety Team using the

If your manufacturing facility is like ours and you need GHS labels on small bottles around the plant, try what's worked for us. All of our small chemical bottles are labeled by our Safety Team using the