A market we're seeing growth in is the smoke-less e-cigarette and vapors industry. Tobacco users have been looking for alternatives to traditional cigarettes that offer a similar experience and the nicotine they crave. These products are also used as replacements for other nicotine-delivery products like gum and patches that help users quit smoking cigarettes.

Smoke-less e-cigarettes products go by lots of names: vaping, vapor, e-juice, e-cigarette liquid and vape juice. You will find a wide variety of labels on the various sizes of vapor juice bottles. And, as with any other industry or product, the labels usually supply more information than just the product name.

What You Should Include On Your Vape Labels

For this products, manufacturers apply the labels to small bottles not much bigger than an eye dropper container. The label itself tends to be around 3" wide and 1.5" tall, depending on the size of the bottle.

Unlike cigarettes and alcohol, the packaging is not FDA regulated because the technology is new. As research of this product grows, we expect to see new requirements for labeling. Keep in mind that you cannot sell this product to minors so avoid branding that appeals to children. Other things to include on vapor juice labels are warnings, relevant storage information and content information.

Currently the FDA is reviewing the comments made by vapor manufacturers on their 2014 regulation proposal.

Currently the FDA is reviewing the comments made by vapor manufacturers on their 2014 regulation proposal.

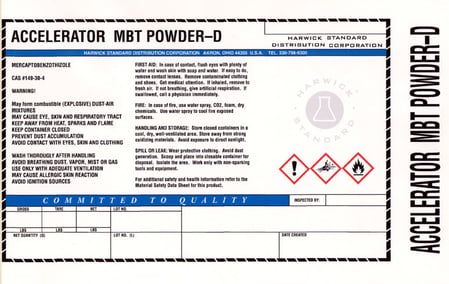

To be ahead of the game, consider including these elements on your e-juice labels:

- Ingredients and product content list

- Name and location of the manufacturer

- Nicotine content information

- Quantity information (5mL, 10mL, ect.)

- Nicotine warnings

After you add these elements to your label you should still have space for a branding. Learn more about the FDA proposal at regulations.gov.

Print Techniques for Vapor Labels

There are several ways you can print labels but there are two main printing methods that stand out for e-juice labeling. Take a look.

Epson C3500 Inkjet Label Printer

If you are looking for low volume printing and want to print the labels yourself, the Epson C3500 inkjet printer is a great option. It's affordable and will produce beautiful color labels for your bottles. It can print the most popular vape label size, 3" x 1.5", and can print only as many labels as you need.

Unlike many other ink jet printer options, the Epson C3500 uses pigmented inks which means more print durability for your labels. The inks won't run when subjected to water and most solvents (you would have to test your product on the label to be sure). Keep your product looking great during the life-span of the bottle. Learn more about the Epson C3500 on Go-Label.com.

Custom Printed Labels

Having a printing company produce your labels will allow you to focus on managing other areas of your production and business. It also opens you up to a variety of design options that you cannot create on a stand-alone ink jet printer like laminates, varnishes and foils. As this market becomes more popular, the packaging design will become even more important for a brand. Like we've seen with other emerging markets, if you sell your product at a premium price, the label lets the consumer know it's worth the price.

Having a printing company produce your labels will allow you to focus on managing other areas of your production and business. It also opens you up to a variety of design options that you cannot create on a stand-alone ink jet printer like laminates, varnishes and foils. As this market becomes more popular, the packaging design will become even more important for a brand. Like we've seen with other emerging markets, if you sell your product at a premium price, the label lets the consumer know it's worth the price.

We see this category experiencing fast growth like craft beer. Vapor labels will also need to use their pressure-sensitive labels to grab the attention of consumers, identify their brand easily, and convey the message of that brand while competing in an ever-growing market of start ups.

If you have questions about the two printing options or need some samples labels, contact one of our label experts to walk you through the vape labeling process.

Recently Google put a lot of websites in a bit of a panic when they announced that they were changing their search algorithms, that mathematical formula they use to decide which sites are more relevant to your search and are then served up in your results. Google uses these to decide whether your company shows up on page 1 or page 100.

Recently Google put a lot of websites in a bit of a panic when they announced that they were changing their search algorithms, that mathematical formula they use to decide which sites are more relevant to your search and are then served up in your results. Google uses these to decide whether your company shows up on page 1 or page 100.

The Label's Story

The Label's Story Needless to say, the R&F Imports labels were a big hit. We're proud to announce that this series of labels was recognized with a

Needless to say, the R&F Imports labels were a big hit. We're proud to announce that this series of labels was recognized with a

There are many instances where a label application requires a more durable material beyond that of a typical product label. These

There are many instances where a label application requires a more durable material beyond that of a typical product label. These