So you want to know, "What is a pressure sensitive label?" Are they stickers, product identifiers, labels or a component of brand packaging? Yes! Pressure-sensitive labels are used everywhere from toys, food containers, durable products, medical devices, and corrugated boxes, to craft beer can and bottles, cannabis containers, plastic pouches and so much more.

But what are they?

Let's break it down...

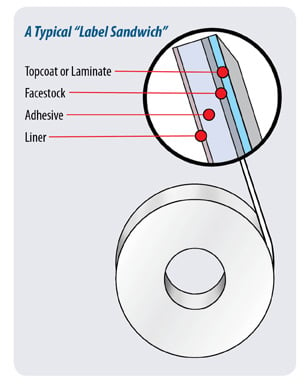

A pressure-sensitive label, or self-adhesive label, is made up of three layers: a face stock, an adhesive and a release liner. We refer to this as the "label sandwich." When a label is manufactured, these three components are sandwiched together to create a label material that can be printed on, laminated, die-cut, and finally peeled off and applied to your product.

Facestock

The facestock is the main part of the label. The material could be paper, film, or metallic foil. This is the layer where the ink is applied on press. For specific applications, a topcoat or laminate may be applied to protect the label artwork or enhance certain areas of the design.

Adhesive

The adhesive is what makes the label stick to the surface of the product or packaging. For glue-applied (cut & stack) labels, this process happens as the label is being applied. A pressure-sensitive label is manufactured to have the adhesive already applied to the face stock when you receive your roll or sheet of labels.

The adhesive type will depend on your application and environment in which the label will be used. Many different types of adhesive are available including versions that stick under cold and wet conditions, some that release easily, some that stick permanently and others that are resealable.

For example, a label that is applied to a durable good, like an air conditioner, will require an adhesive that sticks to metal in an outdoor environment and can last for years. A rubber-based adhesive is aggressive and best for long-life applications.

If the label is only going to be used once, say for a shipping carton label, a strong adhesive isn't necessary. These adhesives are usually acrylic-based and stick more aggressively as they dry, usually over hours or days.

You might even want to select an adhesive that is re-positionable for a peel and redeem coupon.

Liner

The liner is the paper or film that makes up the backing web material. There are options that range from semi-bleached paper or craft paper, to a stronger clear film liner. The liner is coated with a special material that makes it possible to remove the label no matter how strong the adhesive you select.

Paper-based liners are strong yet easily perforated or torn if needed. Film liners are much strong, though slightly more expensive, and work well when there is tension on the label roll when applying the labels.

And there you have it - our label sandwich explained! If you have more questions or want to get more details about label construction, contact us to talk to one of our label experts. They can supply you with samples, quotes or do label testing for your application.

What do automotive parts, power tools, fire extinguishers, electronic components and chemical containers have in common?

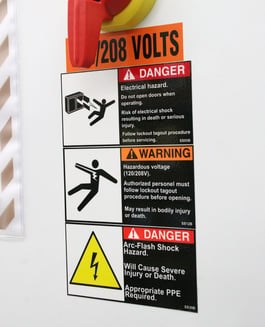

What do automotive parts, power tools, fire extinguishers, electronic components and chemical containers have in common? When it comes to durable goods, labels are for life. These labels can include words, pictures, or both, whatever is necessary to identify the contents and their importance. Labels help customers use and maintain their cars, power tools and appliances. And by delivering directions and critical warnings, labels keep people safe.

When it comes to durable goods, labels are for life. These labels can include words, pictures, or both, whatever is necessary to identify the contents and their importance. Labels help customers use and maintain their cars, power tools and appliances. And by delivering directions and critical warnings, labels keep people safe.

Swanson was approached by one of their customers about a new packaging configuration for two of their largest framing square sizes. Typically, the labeling for these items include a large glossy tagstock material that is stapled or glued together, sometimes with an instructional “blue book” contained within. Because of the odd shape, this is all prepared by hand.

Swanson was approached by one of their customers about a new packaging configuration for two of their largest framing square sizes. Typically, the labeling for these items include a large glossy tagstock material that is stapled or glued together, sometimes with an instructional “blue book” contained within. Because of the odd shape, this is all prepared by hand.  The primary requirement for this label was that it needed to be removable without leaving any residue behind on the high-quality CNC-machined aluminum framing squares that would frustrate the end user. After all, the preferred location of this new label was directly on top of etched distance and angle markings, essential for the use of the product.

The primary requirement for this label was that it needed to be removable without leaving any residue behind on the high-quality CNC-machined aluminum framing squares that would frustrate the end user. After all, the preferred location of this new label was directly on top of etched distance and angle markings, essential for the use of the product.  Next, they asked Weber to find a way to automate the labeling process. The idea was to place a triangle-shaped label on the corner of the framing squares, or a triangle-on-a-triangle. The framing squares have an extended base, or bevel, which allows them to nicely rest along side the length of a piece of lumber and be slid up and down to trace lines for cutting.

Next, they asked Weber to find a way to automate the labeling process. The idea was to place a triangle-shaped label on the corner of the framing squares, or a triangle-on-a-triangle. The framing squares have an extended base, or bevel, which allows them to nicely rest along side the length of a piece of lumber and be slid up and down to trace lines for cutting.

RFID (Radio Frequency Identification) technology has been around for many years. It first caught on in retail and logistics as a natural fit. Items with RFID labels, also referred to as Smart Labels or Intelligent Labels, can be tracked and identified efficiently through every stage of the supply chain, from purchasing to shipping to delivery.

RFID (Radio Frequency Identification) technology has been around for many years. It first caught on in retail and logistics as a natural fit. Items with RFID labels, also referred to as Smart Labels or Intelligent Labels, can be tracked and identified efficiently through every stage of the supply chain, from purchasing to shipping to delivery. Today, pharmaceutical companies are also recognizing the benefits of RFID labels, and for very good reasons. In pharma, RFID labels help to manage inventory, increase operational efficiencies, remain in compliance with governmental regulation, and ensure the wellbeing of patients and consumers. RFID labels also enable itemizing and sorting of stock to ensure quality and prevent waste.

Today, pharmaceutical companies are also recognizing the benefits of RFID labels, and for very good reasons. In pharma, RFID labels help to manage inventory, increase operational efficiencies, remain in compliance with governmental regulation, and ensure the wellbeing of patients and consumers. RFID labels also enable itemizing and sorting of stock to ensure quality and prevent waste.  It is critical to provide the right drug and of course, one that's free of tampering. RFID not only ensures integrity, it delivers strong counterfeiting deterrence as the label itself could be used to authenticate the pharmaceutical product and tamper evidence.

It is critical to provide the right drug and of course, one that's free of tampering. RFID not only ensures integrity, it delivers strong counterfeiting deterrence as the label itself could be used to authenticate the pharmaceutical product and tamper evidence.  In North America, 250 million blood bag labels are used on average every year, and demand is expected to continue to grow significantly. Giving blood is a simple, straightforward process and donating a pint of blood typically takes less than 12 minutes.

In North America, 250 million blood bag labels are used on average every year, and demand is expected to continue to grow significantly. Giving blood is a simple, straightforward process and donating a pint of blood typically takes less than 12 minutes.  These labels are:

These labels are: