Our world is filled with many complex and complicated products, some of which can be dangerous if handled incorrectly.

And there are times when a product has to have emergency information available to users and first-responders.

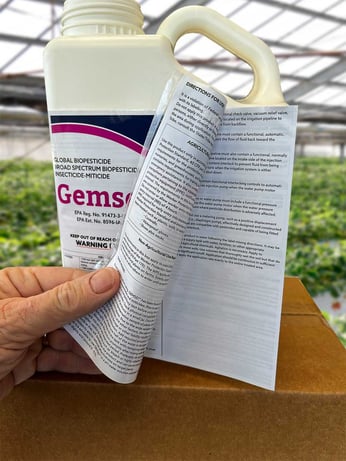

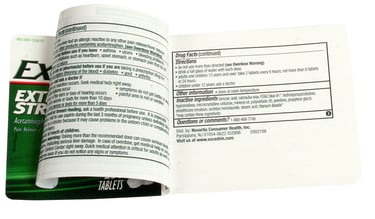

This is where a label called an Extended Text Label comes into play. Extended Content Labels (ECLs) are a family of labels designed to increase packaging space to convey in-depth information. If you've ever seen a bottle or a package with a label that folds or pops out, then you've seen at least one type of Extended Content Label.

ECLs are labels made up of multiple panels attached directly to the package that either unfold or unroll to reveal necessary information, such as regulatory requirements, multi-lingual text, promotions, cautionary messages, and much more.

While traditional labels are printed on one side of a piece of material, ECLs will give you more space for product information like ingredients and instructions and can free space up on the front of your label for branding and essential product information.

These labels are usually produced with a hinged format that opens to reveal additional panels that can even fold out additional pages. When you have a lot to say, these pages can contain all your information relevant to your product or business.

ECLs are perfect for communicating data in multiple languages or meet the needs of specific industry requirements like health warnings, application instructions, or warranty information.These types of labels appear in retail packaging, software product labeling, drug facts information, MSDS information, on personal care products or supplements, and food or beverage nutritional fact information.

Also known as multi-ply labels, peel-back or resealable labels, booklet labels and fold-out labels, they combine a Pressure Sensitive Label and a folded or bound outsert that resembles a printed booklet. There is usually a thin strip of clear laminate that has a removable adhesive that allows the booklet to be held closed when applied, opened when needed, and re-closed when done.

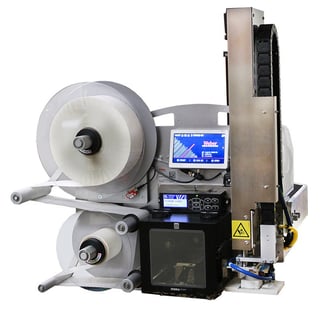

Here is a quick video of an extended text label being printed at Weber packaging Solutions.

Watching the video you can see the printed information, usually printed by an offset printer, is fed into the label press where it is sandwiched between the label of label material and the protective laminate covering. It is then die-cut and wound on rolls for use on a label applicator at the manufacturer's facility.

This kind of label becomes important when packaging profiles are small and there is not enough room on labels for your message. Extended Content Labels provide space for more graphics and copy through the use of multiple pages. They are all engineered to do the same thing — increase the amount of space available for text and graphics. Expanded content labels contain more space for information than ordinary labels.

Extended content labels allow the outer label to be decorative and market the product and brand, while the internal layers contain vital information to comply with regulations and inform the consumer about necessary product details.

Extended content labels allow the outer label to be decorative and market the product and brand, while the internal layers contain vital information to comply with regulations and inform the consumer about necessary product details.

The most common applications are for pharmaceutical products, clinical trials, nutraceuticals, chemicals, pesticides, weed control products, lubricants, cosmetics and more!

- Brand label. If only brand is used on package of a product, this is called brand label. Brand itself is expressed in label. It plays an important role in labelling as it gives information about the brand. It can be removable or non-removable

- Grade Label. Some product have given grade label. It describes the aspect and feature of the product.

- Descriptive label. Descriptive label give information about the feature, using instruction, handling, security. It specifies product usage.

- Informative label

Additional label content that is often completed with extended content, booklet labels or smooth peel labels are the following:

Additional label content that is often completed with extended content, booklet labels or smooth peel labels are the following:

- Instructions

- Multiple languages

- In-store coupons

- Rebate details

- Game and sweepstake pieces

- Recipes and ingredients

- Promo items

- Informational takeaways

- Cross-promotional products

This label offers endless options for customization and meets multi-lingual, regulatory, and marketing objectives. Manufacturing will love it too, there is no adjustment to application equipment required to run this label. The transition is seamless.

ducts and dedicate themselves to just manufacturing.

ducts and dedicate themselves to just manufacturing. “We were famous for our soaps, tire dressings and degreasers, but since 2010, we have pursued the development of polishing compounds for automotive finishes,” said Gernaro. “3D now has compounds that are unmatched in how fast they polish. This one-step compound polishes (removes swirl marks), protects (adds a protective film), and leaves a great shine.”

“We were famous for our soaps, tire dressings and degreasers, but since 2010, we have pursued the development of polishing compounds for automotive finishes,” said Gernaro. “3D now has compounds that are unmatched in how fast they polish. This one-step compound polishes (removes swirl marks), protects (adds a protective film), and leaves a great shine.” When Joseph Weber, Sr. founded what was then known as Weber Addressing Machine Company in 1923, he not only introduced the company’s first handprinter - the Tag-O-Graph - to market but laid a solid foundation for a company that would endure the test of time.

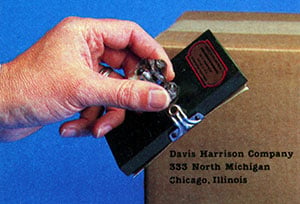

When Joseph Weber, Sr. founded what was then known as Weber Addressing Machine Company in 1923, he not only introduced the company’s first handprinter - the Tag-O-Graph - to market but laid a solid foundation for a company that would endure the test of time. Weber's first product was a simple handprinter that used an ink pad and a stencil mounted on a block of wood with a handle. This allowed the user to mark multiple cartons quickly with the same information. The product line, and the company, grew slowly at first, building a loyal customer base.

Weber's first product was a simple handprinter that used an ink pad and a stencil mounted on a block of wood with a handle. This allowed the user to mark multiple cartons quickly with the same information. The product line, and the company, grew slowly at first, building a loyal customer base. Today, the company remains family-owned and operated by the Weber family, with Doug Weber, Joseph Weber, Jr.’s son, leading the company as President and CEO.

Today, the company remains family-owned and operated by the Weber family, with Doug Weber, Joseph Weber, Jr.’s son, leading the company as President and CEO.

Over the years since Walmart has continued to work with

Over the years since Walmart has continued to work with