“It's a team effort–that's why we're here 90 years."

To celebrate our 90th anniversary, we asked some of our employees what this milestone means to them. We were flattered to hear that they believe in us as much as we care about them–a testament to why we’re still in business after all these years.

Here’s what they had to say:

Our President/CEO Doug Weber, the grandson of Joseph Weber Sr, said, “It’s something we can be very proud of. This isn’t just something one individual, one person can do, but really, it’s the whole organization–those that preceded us and those that will be part of our future.”

Watch Doug and his sister Connie’s full interview

"Everybody here is great to work with, and we do so well together as a team,” said Jim Vanderwiel, our Manager of Systems Engineering. “It's not just an individual, it's a team effort by the company–that's why we're here 90 years."

Listen to Jim’s testimonial

“Weber has always been a very iconic company,” said Harrison Chien, our Vice President of Sales & Marketing. “It's a company I’ve always admired throughout my career, and being here is being part of this group, part of the family. There’s a lot of pride that I think our employees and especially myself have, and it’s a testament, really, to the Weber family.”

See the full interview

Oscar Altergot, our Senior Press Operator, said, “When Mr. Weber started this company, he had a goal to produce high quality equipment and labels for the customers. And 90 years later, here we are, still doing the same thing.”

Hear what else Oscar had to say

“The years that people have worked for Weber certainly makes me feel good about working for Weber–because I feel needed,” said William Laboy, Lead Field Service Engineer. “I feel that they appreciate everything you do for them.”

Listen to William’s full interview

Todd Peterson, Production Manager, shared, “I’ve been here over 36 years, I've had my wife working here, I’ve had my son working here, I've had my daughter-in-law working here. So, at one time, there were four of us working here in this plant. Weber’s 90 years means a lot to us. We’re a very grateful family.”

See what else Todd had to say

“Weber has really helped out a lot. It’s been a great relationship. I’m saving about six cents per can by labeling instead of using shrink. A pallet of 100 cases saves me $600 per pallet. Times 10-20 pallets a month, that pays my rent!”

“Weber has really helped out a lot. It’s been a great relationship. I’m saving about six cents per can by labeling instead of using shrink. A pallet of 100 cases saves me $600 per pallet. Times 10-20 pallets a month, that pays my rent!”

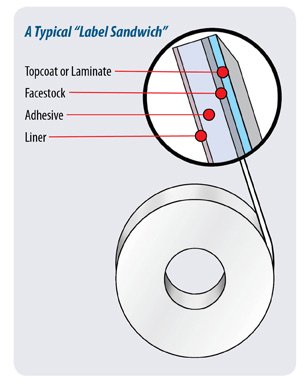

A pressure-sensitive label, or self-adhesive label, is made up of three layers: a face stock, an adhesive and a release liner. We refer to this as the "label sandwich." When a label is manufactured, these three components are sandwiched together to create a label material that can be printed on, laminated, die-cut, and finally peeled off and applied to your product.

A pressure-sensitive label, or self-adhesive label, is made up of three layers: a face stock, an adhesive and a release liner. We refer to this as the "label sandwich." When a label is manufactured, these three components are sandwiched together to create a label material that can be printed on, laminated, die-cut, and finally peeled off and applied to your product.

1964

1964

1984

1984 1998

1998